Fiber-reinforced plastics vs. extruded aluminum: Common Questions Answered

Q: What is the differences between composites and aluminum?

A: Aluminium and composites are two distinct types of materials with different properties, manufacturing processes, and applications. Aluminum is a metal that consists of metallic atoms arranged in a crystalline structure. Composites are materials composed of two or more distinct constituents, typically a matrix material (such as a polymer resin) and reinforcement materials (such as fibers). The combination of materials creates a unique structure with tailored properties.

Q: How does the manufacturing of aluminium profiles differ from composite profiles?

A: Aluminum profiles are typically manufactured through an extrusion process while composite profiles are often manufactured with pultrusion typically using fiberglass-reinforced polymers. Both aluminum and composite profiles have their advantages and the choice of manufacturing process depends on the material's properties, the desired application, design constraints, and other project-specific factors.

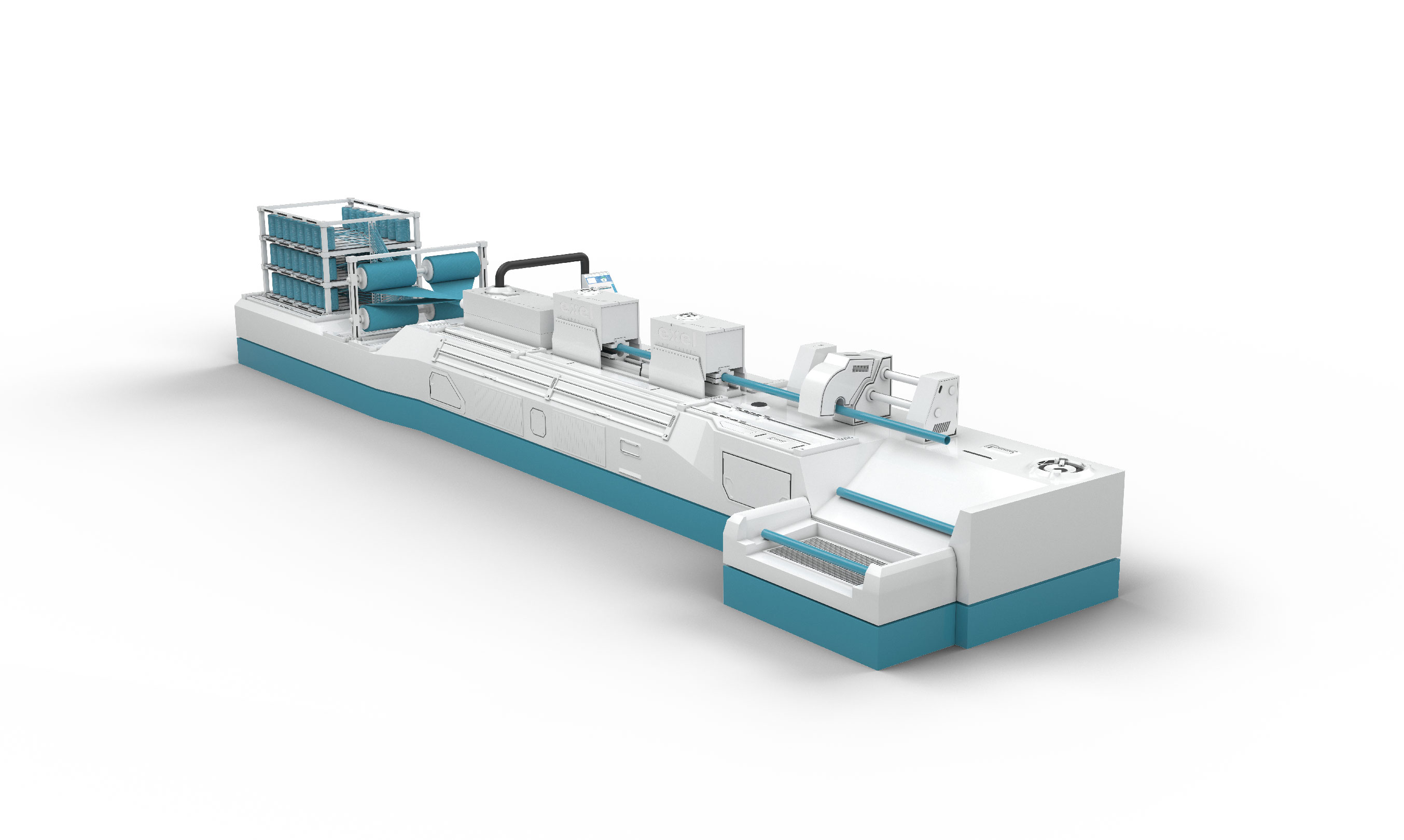

Q: What is pultrusion?

A: Pultrusion is a continuous manufacturing process used primarily for producing composite materials, such as fiberglass-reinforced polymers (FRPs). The process involves pulling fibers (typically fiberglass or carbon fiber) through a resin bath and then through a heated die, where the resin is cured and the profile shape is formed. The resulting pultruded composite profiles are lightweight, corrosion-resistant, and have high strength-to-weight ratios. Exel Composites specializes in pultrusion and pull-winding which are both continuous manufacturing technologies for manufacturing composite profiles.

Q: What is aluminum profile extrusion?

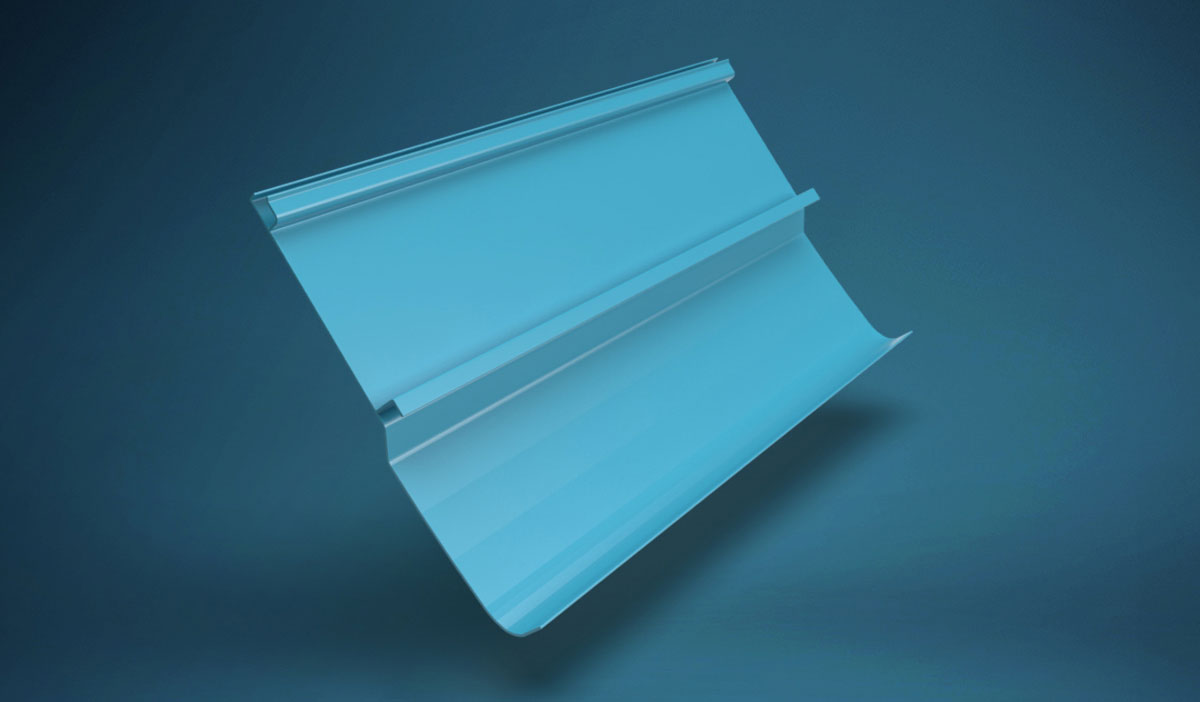

A: Aluminum extrusion is a manufacturing process used to create profiles by forcing heated aluminum billets through a shaped die. The resulting extruded aluminum profiles can have various shapes and sizes and are widely used in industries such as construction, automotive, and consumer goods.

Q: Why choose composites profiles over aluminum extruded products?

A: Composites offer several benefits over aluminum extrusion, particularly in certain applications and for specific requirements. Some of these advantages include higher strength-to-weight ratio, corrosion resistance, design flexibility, electrical insulation, thermal insulation, less need for maintenance and chemical resistance. With continuous composite manufacturing technologies it's also possible to produce wider profiles than with aluminum extrusion. This can result in cost savings and easier installation.