How we work with you to create your

composite tube

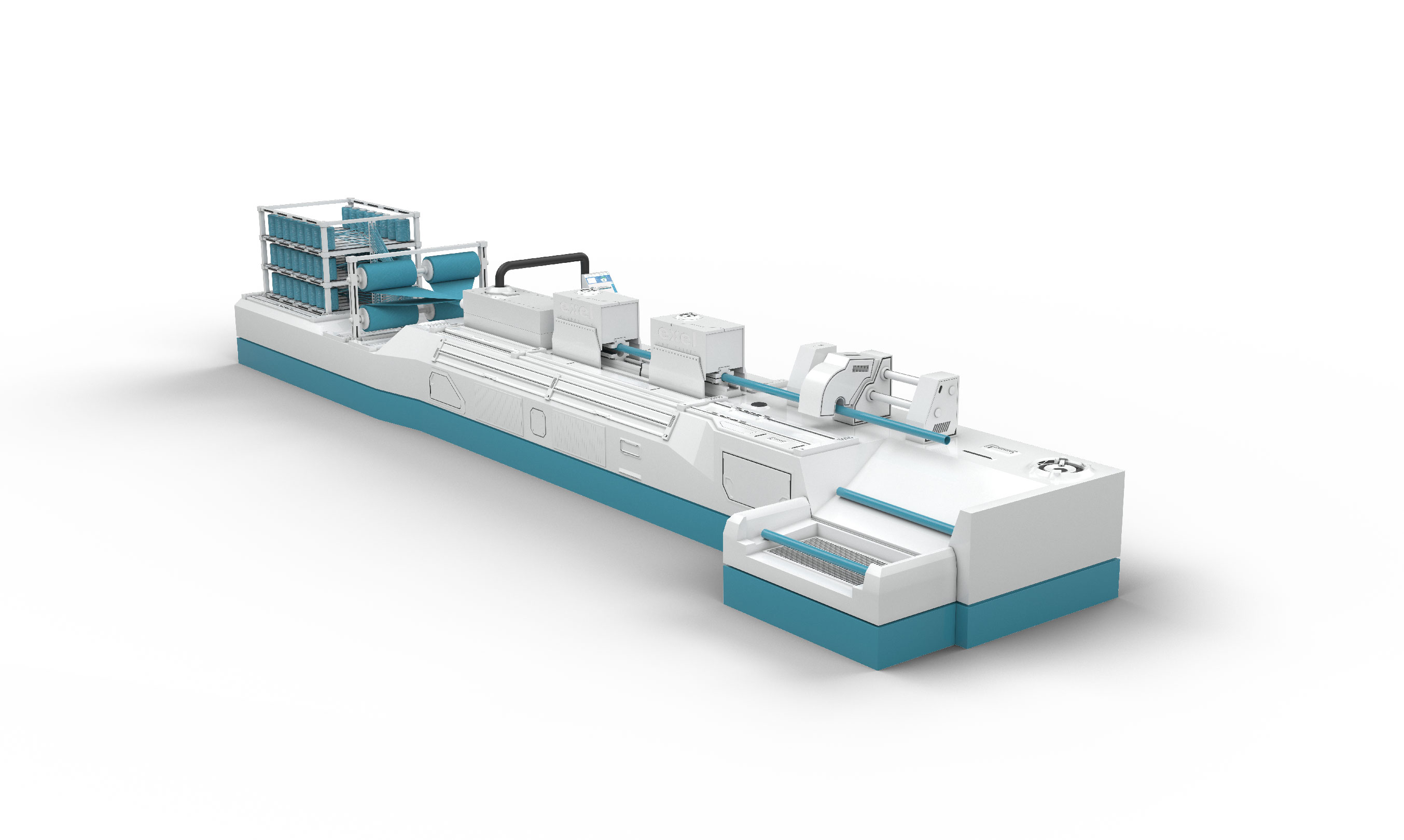

We at Exel Composites specialize in glass fiber and carbon fiber tube manufacturing. The creation of a composite solution is a collaborative process. Our R&D works with your product engineers or R&D to first outline and understand your needs.

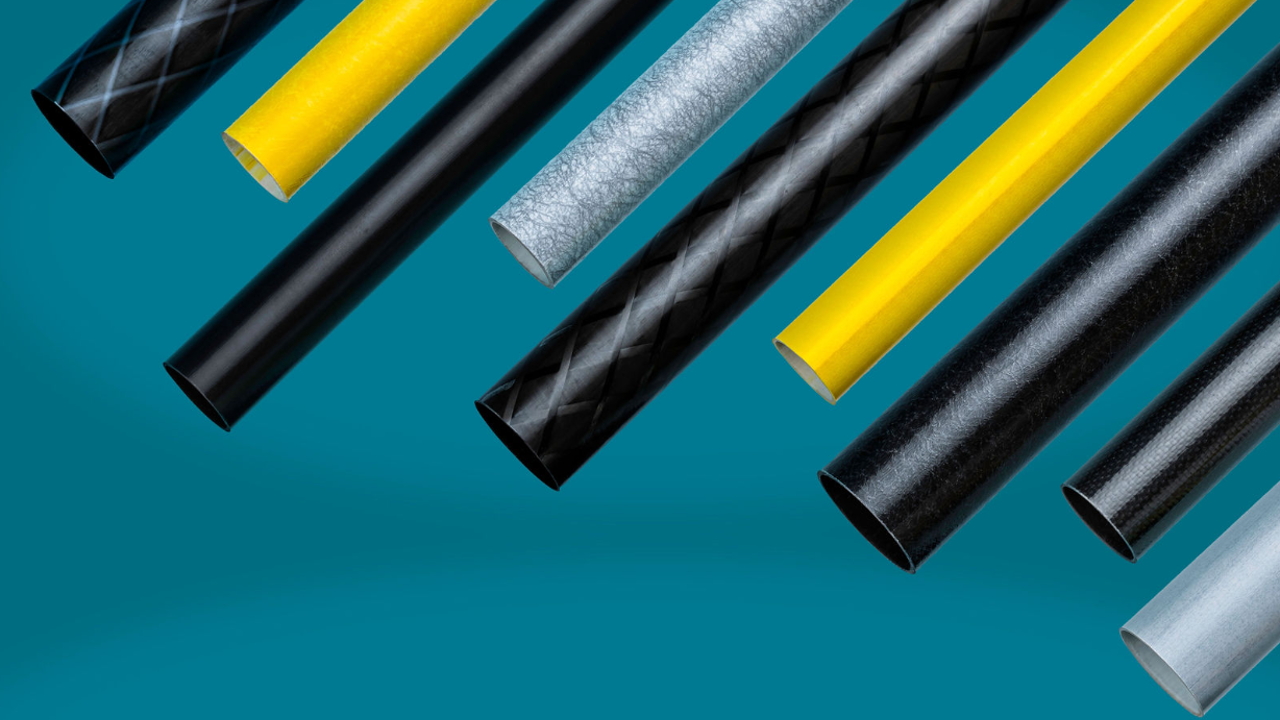

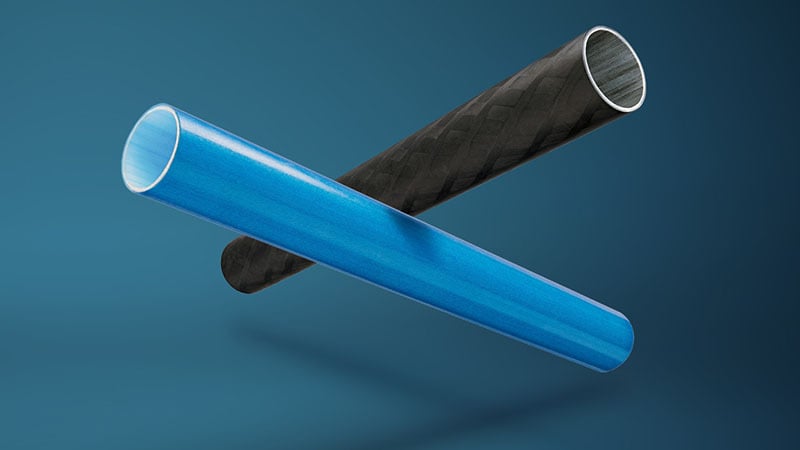

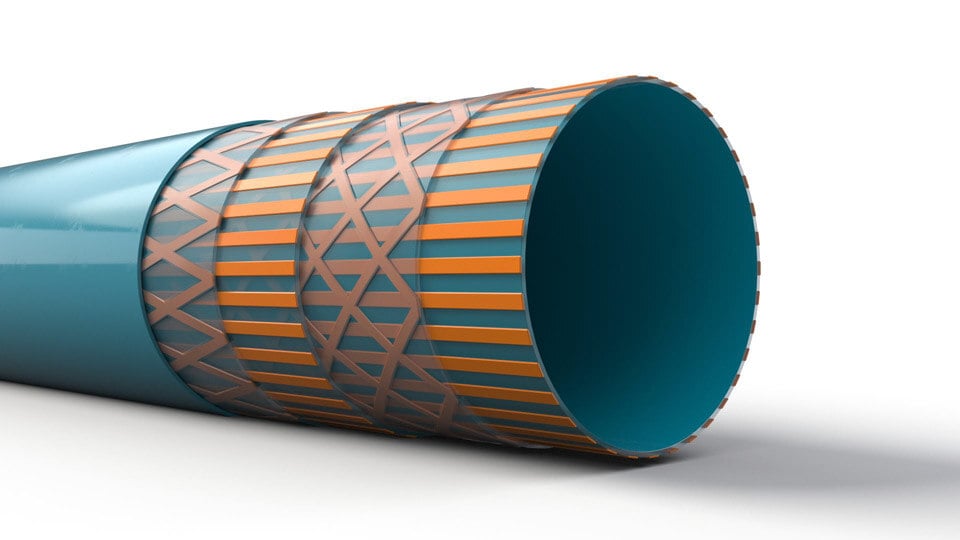

Next, we engineer your composite tube, and work together to test prototypes. The choice of reinforcements and resin system used depends on your requirements. Some solutions use glass reinforcements, some use carbon. Additionally, we can advise on the best use of hybrid composites, where we combine different fiber reinforcements (such as glass and carbon) into your solution, providing many of the benefits of both reinforcements. Once the prototypes are accepted by your team, we move to volume production. Learn more about composite tube possibilities here.

Whether you are looking for carbon fiber pipes, carbon fiber rods or fiberglass tubes for sale, we've got you covered. Get in touch with our team today by filling the form at the top of the page. You can also book a meeting with Marc from our US team via the link below.