Custom engineered composites for your needs

We at Exel Composites specialize in custom engineered composites tailored to your mechanical specifications and aesthetic needs. From carbon fiber composites and glass fiber composites to hybrids, we are the right partner to help you take your products to the next level. Our experienced R&D team has decades of experience working with CFRP and GFRP materials. So whether your looking for structural composites or composites sheets for building & infrastructure or composite panels for transportation, we will help you find the optimal composite solution based on your needs.

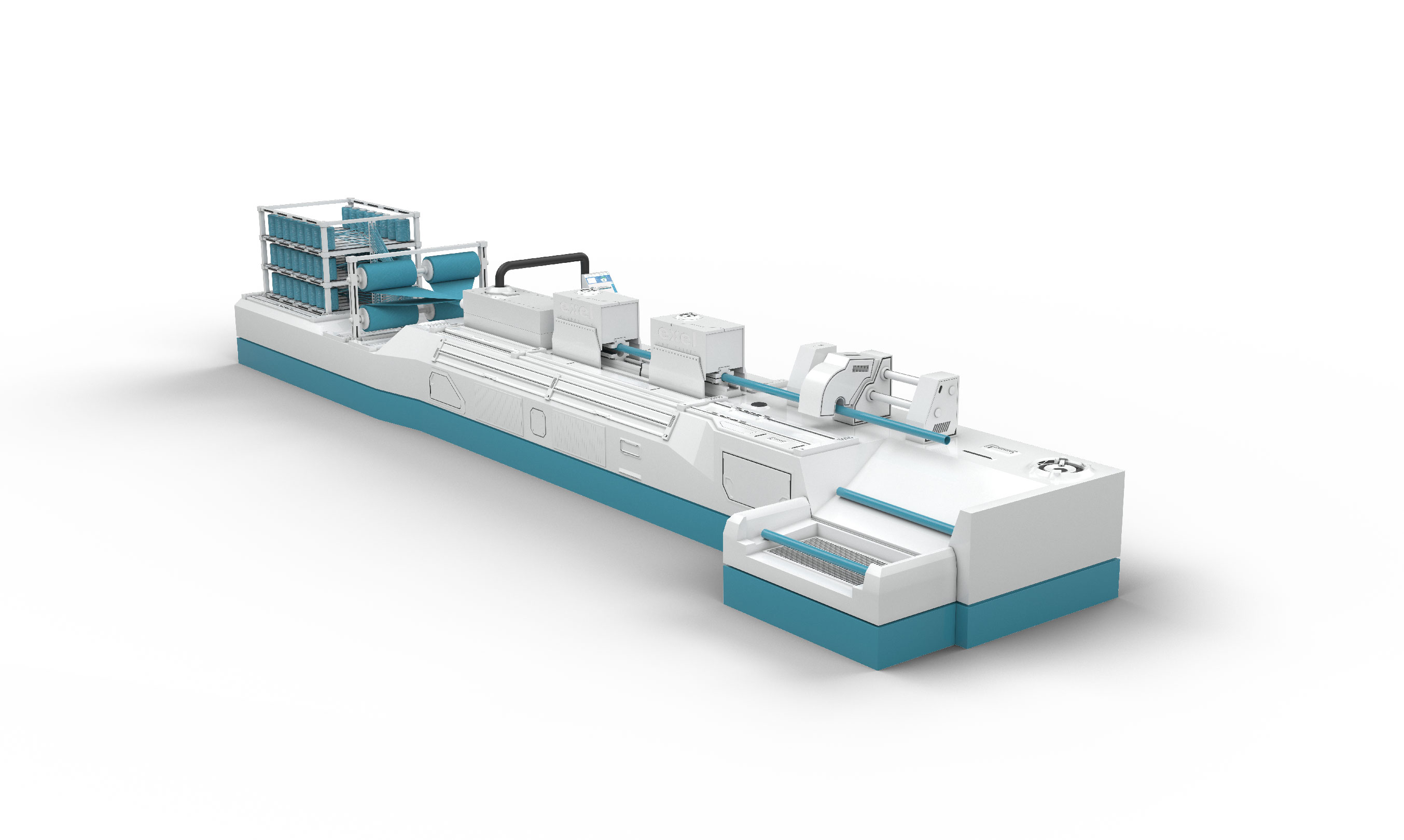

We are experts in continuous manufacturing, including pultrusion and pull-winding which are well suited for high quality volume manufacturing of composite profiles and tubes.

Composites offer various benefits

Composite materials offer a wide range of benefits across various industries and applications due to their unique combination of properties. Some of the biggest benefits of composite materials include: exceptional strength-to-weight ratio, durability, design flexibility, corrosion resistance, fatigue resistance, tailored mechanical properties, thermal and electrical insulation and reduced maintenance costs.

FRP Composites solutions for different industries

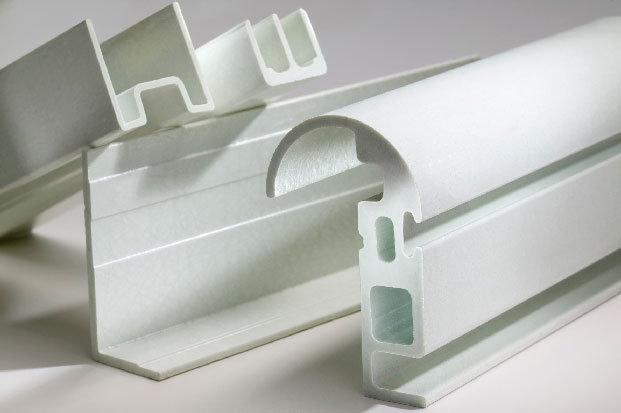

Exel Composites serves several industries and segments with various advanced composites solutions. Our custom pultrusion profiles and pull-winding solutions include:

-

FRP profiles and FRP tubes

-

GRP profiles and GRP tubes

- CFRP profiles

- Glass fiber tubes & carbon tubes

-

hybrid composite profiles and tubes

-

thermoplastic composites