Q: What kind of materials, fibers and resins do you use?

A: Composites, also known as reinforced plastics, can be made from different fiber and resin combinations. We manufacture both glass fiber composites and carbon fiber composites as well as hybrids where different fibers can be combined in the same profile to achieve different mechanical properties. It is also possible to use natural fibers such as hemp and flax. The interest for natural fiber composites is increasing as OEMs look for ways to reduce their carbon footprint.

Q: What are the advantages of using composite materials over aluminum?

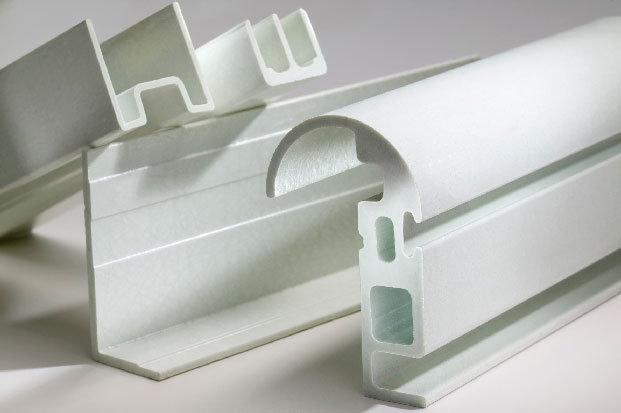

A: Composite materials, like glass fiber reinforced plastics (GFRP) and carbon fiber reinforced plastics (CFRP), offer several benefits compared to traditional aluminum. These advantages include lighter weight, corrosion resistance, wider design possibilities, electrical and thermal insulation properties, reduced maintenance requirements, and the ability to tailor their properties to specific needs.

Q: What kind of manufacturing processes does Exel Composites use?

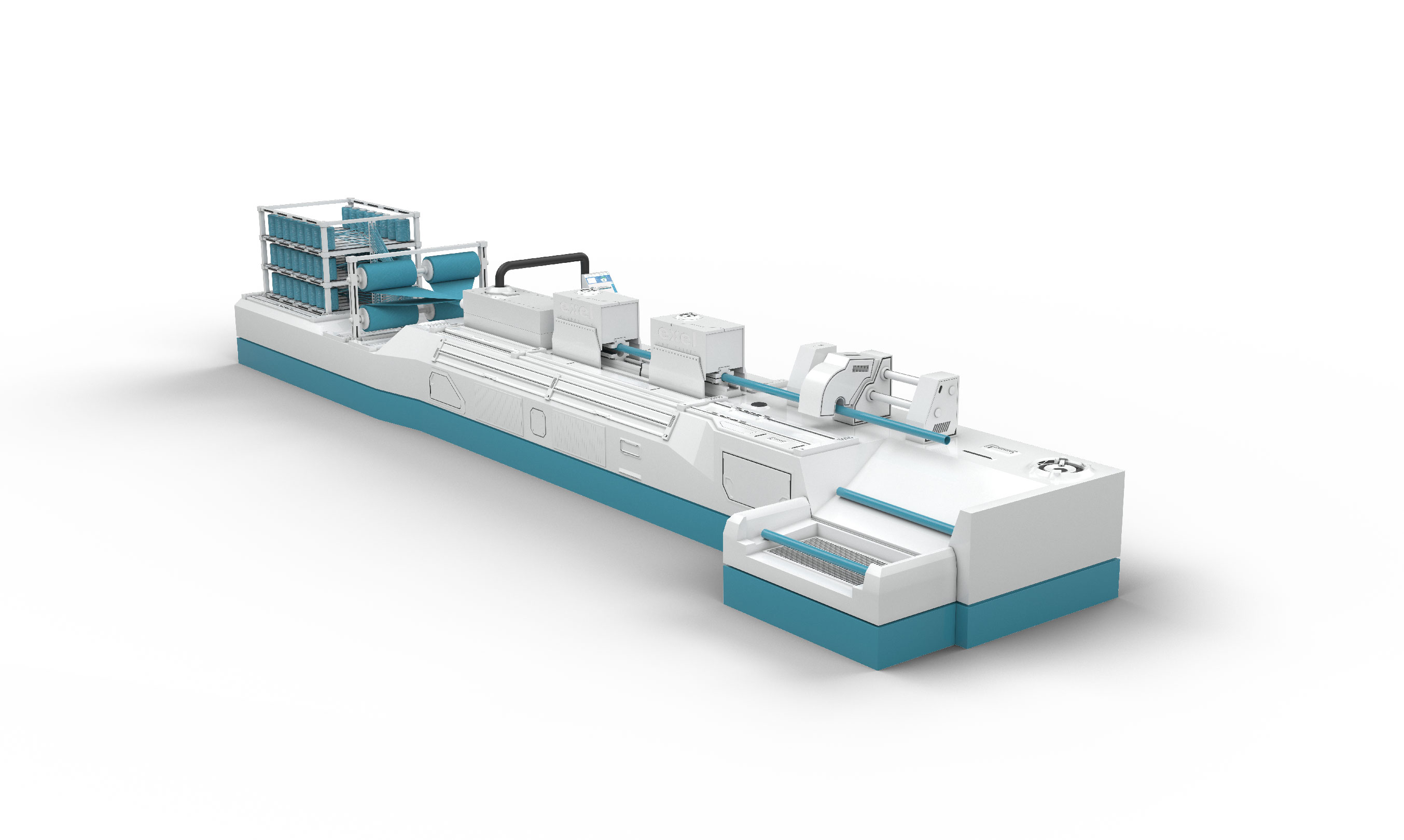

A: Exel Composites specializes in continuous manufacturing technologies including pultrusion, pull-winding and continuous lamination.

Q: What is pultrusion?

A: Pultrusion manufacturing is a continuous process resulting in a steady output of a composite profile which is cut to length at the end of the process. It is called pultrusion because the profile being produced is actually pulled through the process.

Q: What is pull-winding?

A: Pull-winding combines the two techniques of pultrusion and continuous filament winding resulting in a profile with excellent hoop strength, longitudinal strength and modulus, with smooth surface finish. Pull-winding is very similar to pultrusion, with the main difference of adding cross-wound reinforcements. This allows layup configurations with both unidirectional and cross-wound (off-axis) fiber alignments.

Q: Does Exel Composites have a factory in the US?

A: Exel Composites has its own composite manufacturing plant in Erlanger Kentucky. Exel acquired a company called Diversified Structural Composites back in 2018. The acquisition made Exel Composites the only pultrusion company with significant presence on all three major continents.

Q: What kind of industries do you serve?

A: We produce composite solutions for various industries including for example composite panels for transportation, structural profiles for building and infrastructure and composite tubes for various industries like cleaning and maintenance, defense, medical applications and sporting equipment.