Q: What are composites?

A: Composites, also known as fiber glass reinforced plastics (or sometimes referred to as glass reinforced polymers or carbon fiber reinforced polymers) are synthetic materials comprised of reinforcements (fibers) and a matrix (resin). On their own, these materials only provide limited use, however when cured into a composite in a heated dye, the new material provides many useful advantages.

Q: What kind of materials, fibres and resins do you use?

A: Composites can be made from different fibre and resin combinations. We manufacture both frp fibreglass composites and carbon fibre composites as well as hybrids where different fibres can be combined in the same profile to achieve different mechanical properties. It is also possible to use natural fibres such as hemp and flax. The interest for natural fibre composites is increasing as OEMs look for ways to reduce their carbon footprint.

Q: What kind of manufacturing processes does Exel Composites use?

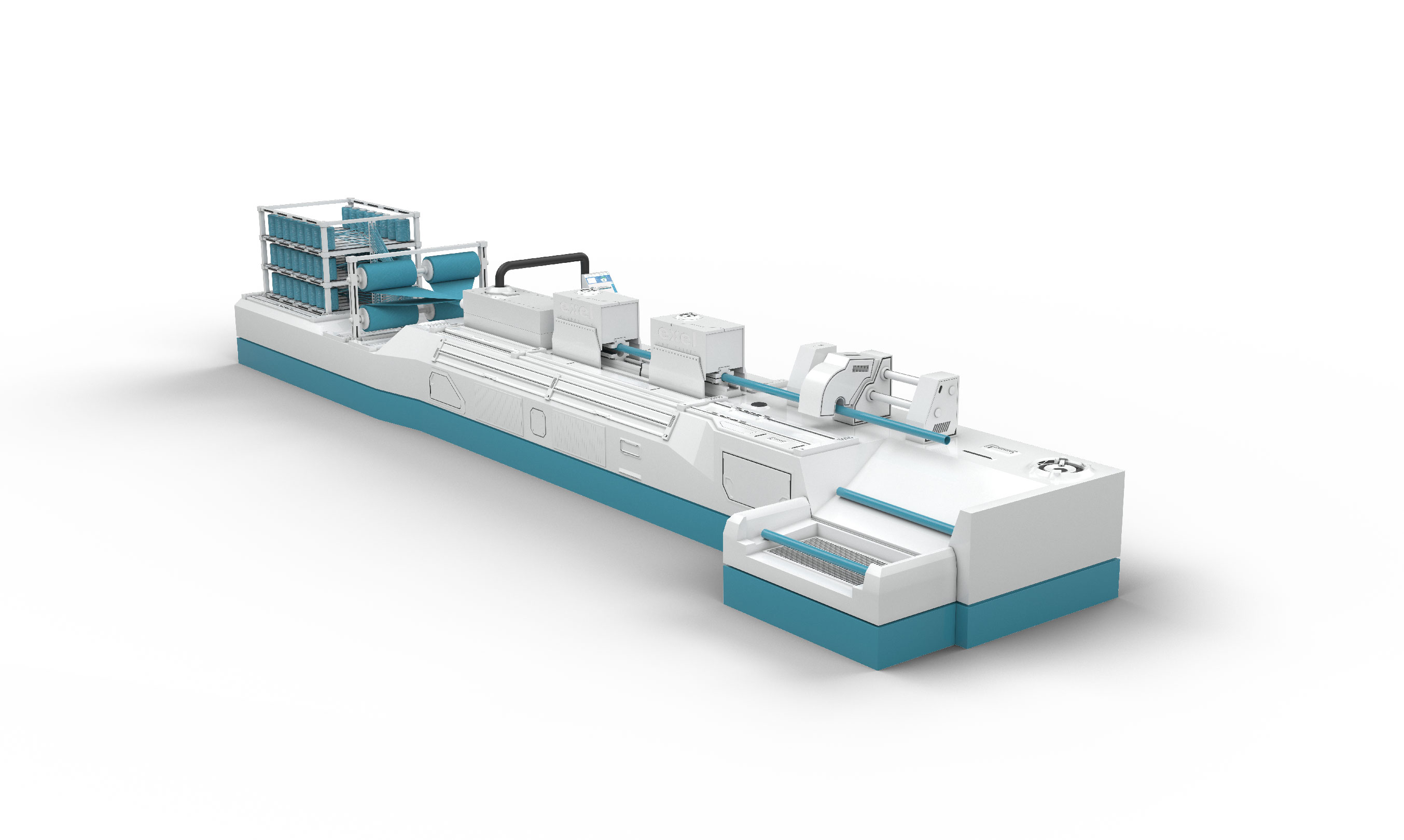

A: Exel Composites specializes in continuous manufacturing technologies including pultrusion, pull-winding and continuous lamination. Pull-wound and pultruded composites come with many benefits. As the processes are continuous they provide repeatable quality and volume output.

Q: What is pultrusion?

A: The pultrusion process is a continuous manufacturing technology for composites resulting in a steady output of a composite profile which is cut to length at the end of the process. It is called pultrusion because the profile being produced is actually pulled through the process on the manufacturing line.

Q: How does pultrusion differ from prepreg manufacturing?

A: Pultrusion and prepreg are two distinct processes used in the manufacturing of composite materials, and they differ in their methods and characteristics. Pultrusion is a continuous manufacturing process while prepreg involves pre-impregnating fibers with resin and profiles are usually manufactured in batches or rolls.

Q: What is pull-winding?

A: Pull-winding combines the two techniques of pultrusion and continuous filament winding resulting in a profile with excellent hoop strength, longitudinal strength and modulus, with smooth surface finish. Pull-winding is very similar to pultrusion, with the main difference of adding cross-wound reinforcements. This allows layup configurations with both unidirectional and cross-wound (off-axis) fibre alignments.

Q: Does Exel Composites have a presence in Australia?

A: Exel has a local sales team In Australia ready to support you with your composite needs. Get in touch with us today by filling the form on the page.

Q: Do you have any stock offering for composite profiles in Australia?

A: We maintain a stock of composites products at our Melbourne facility. The in stock products we offer include for example: fiberglass gratings (FRP grating), fiberglass tubes, fiberglass rods, carbon fibre tubes, carbon fibre tubes, pre-preg glassfibre tubes and FRP threaded rods and flanged nuts. Visit our webshop here.

Q: What kind of industries do you serve?

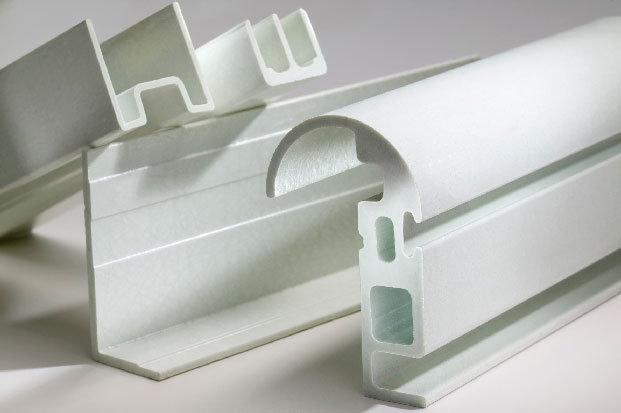

A: We produce composite solutions for various industries including for example composite frp panels for transportation, structural profiles and frp sheets for buildings and infrastructure, insulated rail joints for railway infrastructure and composite tubes for different applications like weather masts and airport masts, cleaning and maintenance tools, defense, medical applications and sporting equipment.

Q: What kind of composite profiles do you manufacture?

A: We manufacture pultruded and pull-wound composite profiles and tubes for various products and applications. From fibreglass reinforcement structures for water filtering systems to composite tubes for cleaning and maintenance tools, our experts are ready to help you find the optimal composite solution for your needs.

Q: Do you make thermoplastic composites?

A: Exel manufacturers bespoke thermoplastic composites based on customer needs. Get in touch with us for more details.